During the operation of the car engine, the electrodes of the spark plugs are continuously worn out. The spark gap increases, gradually reaching the limit value at which interruptions begin to occur in the spark formation. All kinds of mechanical conduction of the insulator and electrodes are also possible, in addition, the latter are eventually covered with carbon deposits.

Therefore, it is recommended to dismantle the candles for inspection and cleaning approximately every 10 thousand km of mileage. By their appearance, by the way, it is possible to judge not only the serviceability of the spark plugs themselves, but also to conclude about the condition of the engine, the quality of the fuel used, oil, etc.

Mainly for this purpose, the color and amount of carbon deposits on the electrodes are analyzed. You can usually see the following:

Light gray, as well as light brown plaque, evenly distributed over the surface in a thin layer. Such a raid indicates the proper operation of the engine and candles. Usually, you only need to remove deposits and, possibly, adjust the gap.

Black soot (matte). In terms of fuel, if available, there is an increased consumption, starting the car may be difficult, and the engine is unstable. There may be several reasons at once:

- high wear of the cylinder-piston group, leaky valves, low compression;

- the candle is too “cold” for a particular engine;

- the spark gap is set incorrectly or there is a crack in the insulator;

- the air filter is dirty.

Black oil residue (shiny). Such deposits can only indicate the ingress of lubricant into the combustion chamber. To eliminate the defect, you will have to change the piston rings or oil-removing valve caps.

Loose deposits covering the electrodes with a thick layer. The most likely reason is the use of low—grade oil or low-quality gasoline. In this case, change the engine oil before replacing the candles, do not forget to flush the lubrication system before doing so.

Red plaque. It is formed when using fuels with an abnormal content of iron-containing additives. With such deposits, there may also be a difficult start and unstable operation of the motor.

Separately, defects such as melting of the electrodes, their burnout, the formation of cracks on the insulator or its partial destruction can be noted. This may be a consequence of the use of “hot” candles for this engine, a malfunction of the cooling system, as well as the use of fuel with an unacceptably low octane number.

Spark plug replacement rules

The disassembly of the candles must be carried out exclusively on a cold engine. Care must be taken, as careless and improper actions can, in the worst case, lead to damage to the cylinder head.

Dismantling is carried out in the following sequence:

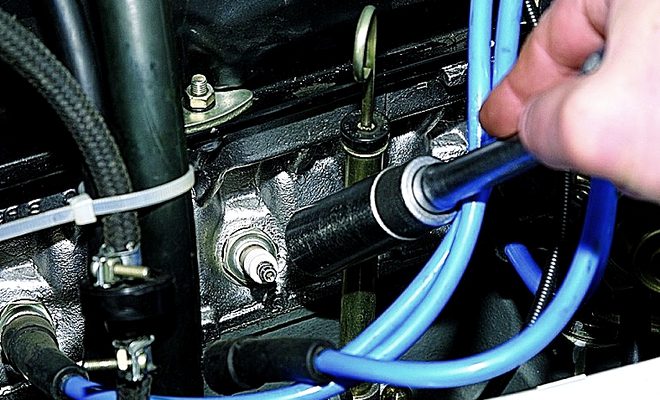

- The tip of the high voltage wire is removed. It is not allowed to pull directly on the wire.

- The area around the candle is either purged with compressed air or cleaned with a brush to avoid dirt entering the cylinder.

- The candle is unscrewed. At the same time, the presence of an O-ring on the base is checked. Sometimes it stays on the engine.

- Next, you can inspect and clean the spark plug, if you do not plan to screw in a new one.

Installation on the engine is performed in the following sequence:

- On a new candle, check the presence and type of the O-ring, the marking, and the size of the gap.

- Wrap the candle by hand until it stops.

- Using a torque wrench, tighten the thread to the point specified in the instructions.The force should usually be 30-45 N*m for a flat O-ring with a thickness of 1.4-2 mm, or 20-25 N*m for a conical O-ring.

If there is no torque wrench, the following recommendations are usually followed:

- for new candles with a flat ring, the thread is stretched by 90 degrees;

- for old ones with a flat seal — by 30 degrees;

- candles with conical seals need to be stretched only by 15 degrees.

If you do not follow these rules, you can damage the thread in the candle well. Damage can also be caused (in addition to excessive tightening) by dirt on the thread or the use of an unsuitable key, causing a misalignment.

It happens that when the candle is screwed in by hand, it goes very tight. It is impossible to use excessive force and permanently disable the thread in the candle well. Instead, you just need to fix it, and if you don’t have the right taps at hand, the time-tested simplest method will do. You will only need a hacksaw or an abrasive, as well as an old unusable candle. On its threaded surface, using these tools, four longitudinal grooves should be made perpendicular to the turns, after which a homemade tap can be used to correct the thread.

Avaruosad.ee – online auto parts store

Need spare parts for your car? Call for free consultation:

- +372 56 812 812

- info@avaruosad.ee